Common Framing Mistakes (And How to Avoid Them)

Common Framing Mistakes (And How to Avoid Them)

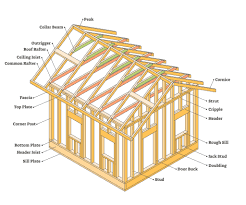

Framing is the skeleton of a building—get it wrong, and you’ll face costly fixes, safety risks, and long-term structural problems. Whether you're a DIY enthusiast or a professional builder, avoiding these common framing mistakes will save you time, money, and headaches.

1. Incorrect Stud Spacing

The Mistake:

Using inconsistent or improper spacing between wall studs (e.g., 24" instead of 16" on center).

Why It’s a Problem:

-

Weakens wall stability.

-

Causes issues with drywall, sheathing, and insulation installation.

-

May violate building codes.

How to Avoid It:

-

Follow local building codes (most require 16" on center for load-bearing walls).

-

Use a layout stick or pre-marked tape measure for accuracy.

-

Double-check spacing before securing studs.

2. Poorly Aligned or Uneven Plates

The Mistake:

Top and bottom plates are misaligned, or the floor isn’t level before framing begins.

Why It’s a Problem:

-

Causes walls to bow or lean.

-

Creates gaps in sheathing and siding.

-

Leads to uneven doors/windows.

How to Avoid It:

-

Always check floor levelness before framing.

-

Use a laser level or chalk line to ensure plates are straight.

-

Shim low spots before securing the bottom plate.

3. Ignoring Load-Bearing Requirements

The Mistake:

Removing or improperly supporting load-bearing walls without proper headers or beams.

Why It’s a Problem:

-

Can lead to sagging floors, cracked walls, or even collapse.

-

Fails building inspections.

How to Avoid It:

-

Consult structural plans or an engineer before modifying load-bearing walls.

-

Install proper headers (LVL, steel, or solid lumber) over openings.

-

Use temporary supports during demolition or modifications.

4. Incorrect Header Sizing

The Mistake:

Using undersized or improperly supported headers for doors and windows.

Why It’s a Problem:

-

Causes sagging over time.

-

Compromises structural integrity.

How to Avoid It:

-

Follow span tables or engineering specs for header sizing.

-

Use double or triple studs at each end for proper load transfer.

-

When in doubt, go bigger—it’s better to overbuild than underbuild.

5. Skipping Proper Bracing & Sheathing

The Mistake:

Failing to install temporary bracing during framing or inadequate wall sheathing.

Why It’s a Problem:

-

Walls can shift before sheathing is installed.

-

Weakens resistance to wind and seismic forces.

How to Avoid It:

-

Use diagonal or T-bracing on walls before sheathing.

-

Install OSB or plywood sheathing correctly (staggered seams, proper nailing).

-

Follow local wind and seismic bracing requirements.

6. Improper Notching & Drilling of Studs

The Mistake:

Cutting excessive notches or oversized holes in studs for plumbing/electrical.

Why It’s a Problem:

-

Weakens studs, leading to structural failure.

-

May violate building codes (many limit notches to 1/3 of stud depth).

How to Avoid It:

-

Use metal plates to protect wiring/pipes near edges.

-

Drill holes centered in studs (max 40% of stud width).

-

Avoid notching in the middle third of a stud.

7. Misaligned Corners & Intersections

The Mistake:

Framing corners and wall intersections with gaps or weak connections.

Why It’s a Problem:

-

Creates insulation and air leakage issues.

-

Makes drywall installation difficult.

How to Avoid It:

-

Use three-stud corners or California corners for better insulation.

-

Ensure intersecting walls are securely nailed (16d nails every 16").

-

Check for plumb and square before sheathing.

8. Ignoring Moisture & Termite Protection

The Mistake:

Failing to use pressure-treated lumber where needed or skipping termite shields.

Why It’s a Problem:

-

Leads to rot, mold, and pest infestations.

-

Shortens the lifespan of the structure.

How to Avoid It:

-

Use pressure-treated wood for:

-

Sill plates on concrete

-

Areas near moisture (bathrooms, basements)

-

-

Install termite shields in high-risk regions.

Final Checklist to Avoid Framing Mistakes

✅ Measure twice, cut once – Precision prevents errors.

✅ Follow building codes – Don’t guess on structural requirements.

✅ Use quality materials – Don’t cut corners with subpar lumber.

✅ Brace walls before sheathing – Prevents shifting.

✅ Consult pros when unsure – A little expert advice saves big repairs.